Machine vision ensures maximum product quality. The powerful, scalable systems inspect flexibly and with high performance. The data collected in the automatic inspection process is also the basis for future-oriented developments such as closed loop and predictive maintenance, thus paving the way for intelligent pharmaceutical production.

Smart Production Smart Factory built on Machine Vision

How inspection data optimize pharmaceutical production processes

In pharmaceutical production, machine vision stands for reliable product quality without recalls, efficient and stable processes as well as powerful and scalable inspection systems. This technology also provides the data for future-oriented developments such as predictive maintenance and fast feedback loops – and thus for the smart factory of tomorrow.

Machine vision as enabler

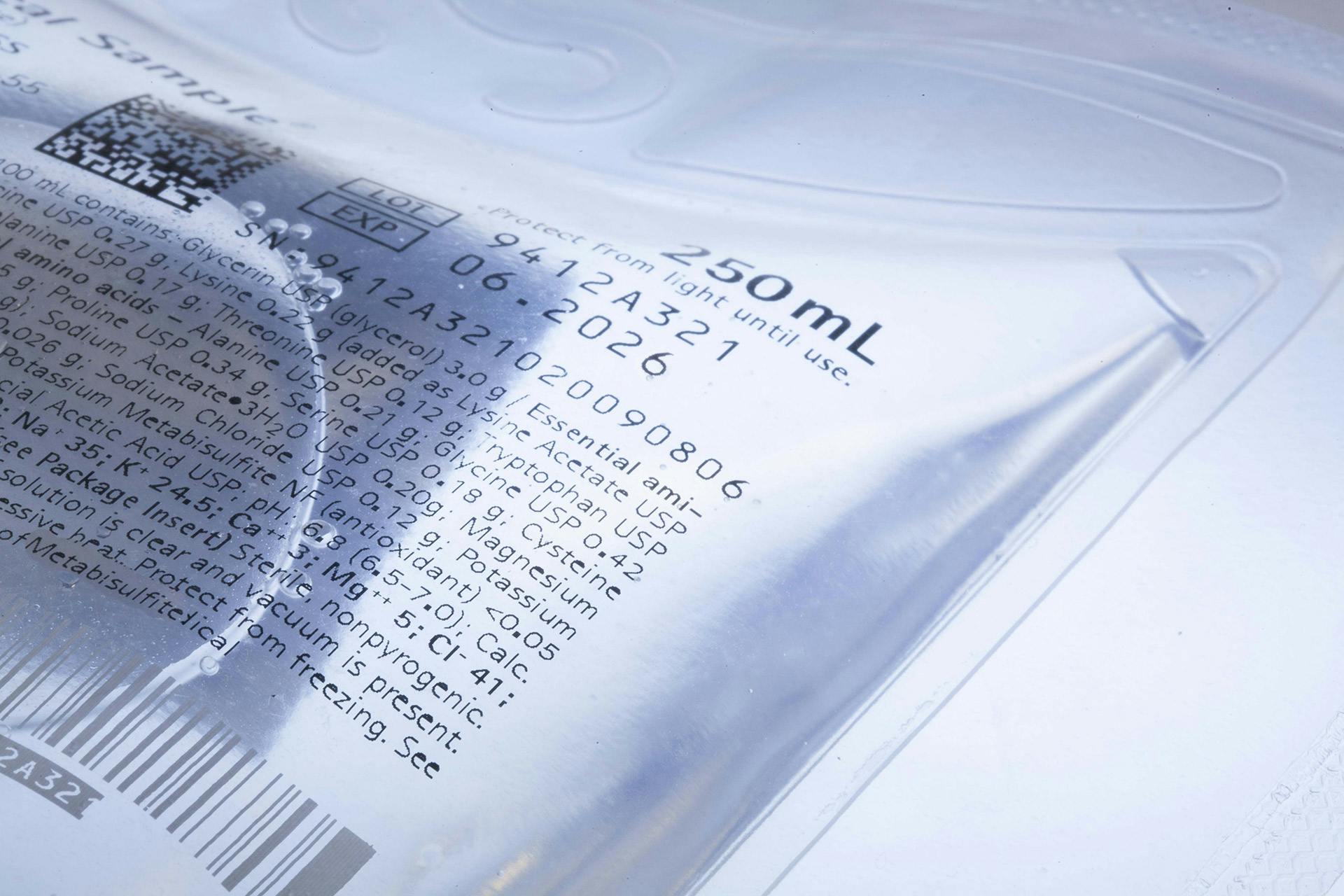

Continuous increase in production, growing automation and higher cycle rates in the pharmaceutical industry – machine vision, i.e. the ability of a computer to "see", is a key enabler in this context, helping manufacturers to reduce costs, enhance quality and streamline processes. Parallel to this, machine vision technology has developed rapidly: it takes on very complex inspection tasks and also collects a large amount of data. Particularly in pharmaceutical production, strict regulations and increased safety requirements must be met while at the same time enabling the highest possible throughput during inspection. This requires an extremely powerful and intelligent vision system, with hardware and software components that are precisely tailored to the respective inspection requirements.

Machine vision is an important and integral part of pharmaceutical production. The vision systems automatically monitor product safety and additionally provide data for Industry 4.0.

Our vision: the smart factory

Data obtained in the automatic inspection process offer enormous potential. One of the major challenges of the future will be to use it even more intelligently. We always speak of Smart Data when it can be used for automation and process control on the basis of intelligent algorithms. VITRONIC pays special attention to this in its product development. For example, we are working on the use of deep learning methods for individual inspection applications in order to further improve the processes and results in error detection. Another concrete field of application is the process-related visualization of the collected inspection data in the form of heat maps and trend analyses. These can be used in a variety of ways, for example to optimize process parameters or to determine the changeover time for critical spare parts.

Common language

Standardized interfaces are an important basis for the exchange of this information. To ensure that the systems can communicate in one language in the future, VITRONIC actively supports the OPC UA Machine Vision Initiative. The goal is to simplify data exchange and networking on the automation level which enables a more flexible use of vision systems. Accordingly, an M2M interface based on the "OPC UA for Machine Vision" Companion Standard will be available with the next release of our basic software framework (Q2 2020) as a standard module for all VITRONIC automation solutions.

Machine vision becomes machine learning

A promising development topic is the so-called “Closed Loop”, i.e. the automatic trend analysis in a closed system. Here, in the automated application, the information from inspection is evaluated, fed back directly into the machine control system, where it can automatically correct machine parameters. In other words: The machine adapts automatically. In the “Fast Feedback Loop”, smaller sub-processes are broken down into sensible sub-units in order to identify necessary adjustments as early as possible and to react to them automatically.

Predictive Maintenance

Last but not least, we still see great potential in the area of predictive maintenance. This approach is based on analyzing data and process parameters to predict when a component within the process on the production line will require maintenance or replacement.

These measures enable the manufacturer to significantly increase the output quantity and reduce downtimes at the same time.

Intelligent teach-in

The pharmaceutical packaging industry is increasingly processing smaller batches. This calls for more flexible lines that can be converted within a short time. More flexibility is therefore also required from inspection systems. On the one hand, they must be scalable to different product variants and, on the other hand, they must allow the simplest possible changeover, which can also be carried out by the user. Intelligent algorithms that automate the teach-in process for a large number of product variants as far as possible with software support surely can help here.

Summary

Machine vision in pharmaceutical production

- Machine vision takes over complex inspection tasks in pharmaceutical production

- Scalable, automated production requires flexible, intelligent inspection systems

- VITRONIC fields of development: Closed Loop, Predictive Maintenance and Deep Learning