By integrating inspection and process data from welding lines, causes of faults can be immediately identified, eliminated, and even prevented.

Smart Production Optimizing the welding process through integrated data

Are self-optimizing welding lines possible?

No defective weld seam may leave production: This is one of the irrevocable laws in the series production of safety-relevant vehicle parts.

But a complete visual inspection is only the last step: the better option is to prevent defective welds and rejects from the outset. How can you optimize the welding process to this end – without long downtimes and with as few manual interventions as possible?

It won’t work without automated inspection

To optimize processes, you need data. As the term Big Data implies: the more, the better. Today, testing and optimization is still often based on empirical values, which are nothing more than "data collected in the head". However, these are difficult to evaluate and depend on the individual inspectors and engineers.

This is where manual visual inspection of welds reaches its limits: Trained human inspectors may be similarly accurate or more precise at certain points than automatic inspection using industrial image processing. But only the latter measures and documents all the data of each weld seam without gaps, such as dimensions or volume, and above all discrepancies, i.e., defects.

Dozens of data records are captured for each weld seam, which you can now use for optimization.

Link test data and process data

However, inspection data alone will only take you so far: they do not reveal what caused the defects. Only with this knowledge can you optimize the welding process and eliminate the sources of error.

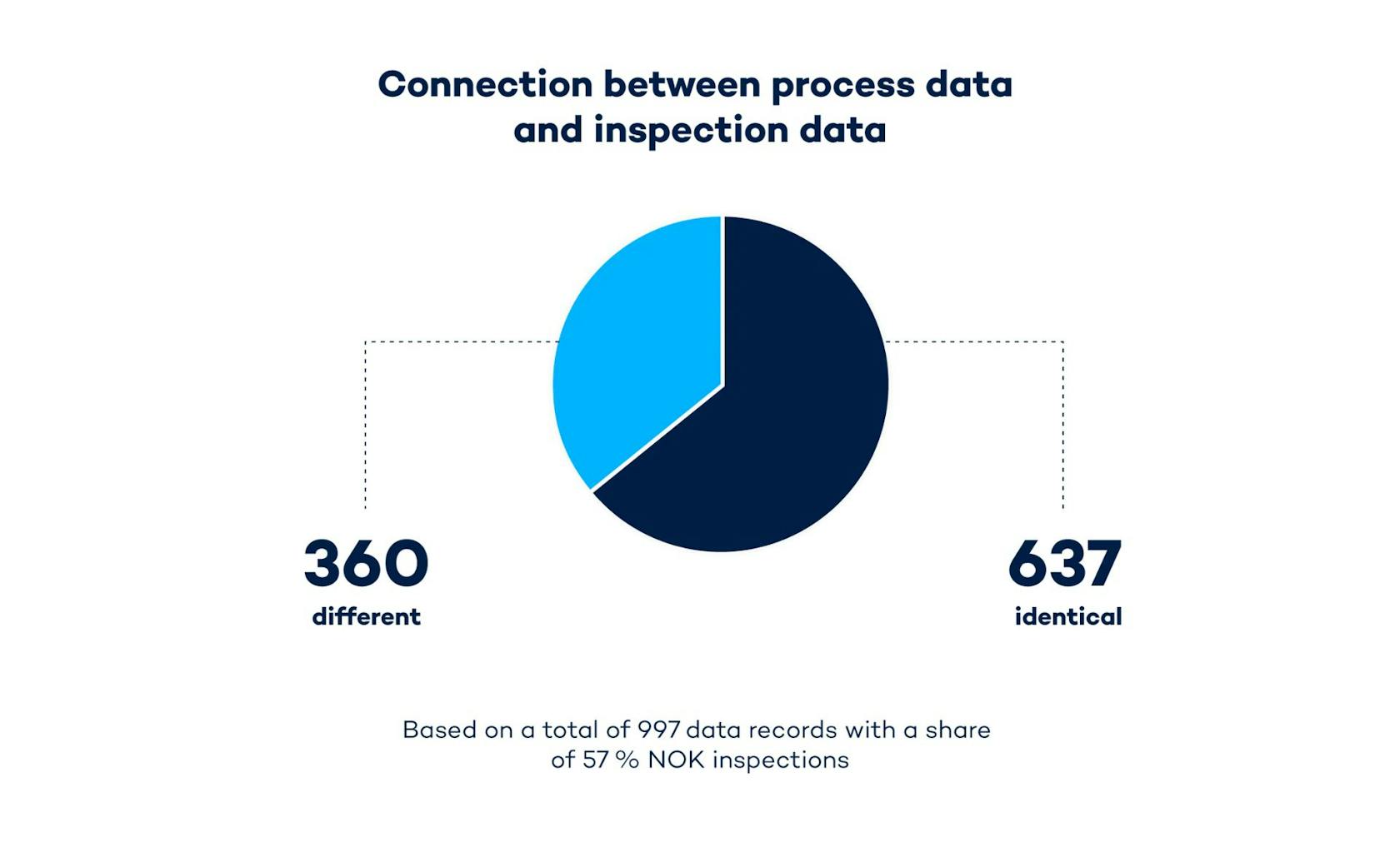

To achieve this, you need to compare the inspection data (of the image processing) with the process data (of the welding process) of a production part. By comparing the two sets of data, you can figure out the cause of around 60 percent of all welding defects.

This was the result of an examination of almost 1,000 weld seam inspections, which you can see in this graphic:

However, it doesn’t help much if you have these data in separate systems. You would have to manually compare thousands of data and analyze measured values individually: a task that is hardly feasible.

Only by integrating all data, you can significantly accelerate troubleshooting and process optimization – and even automate it. How does it work?

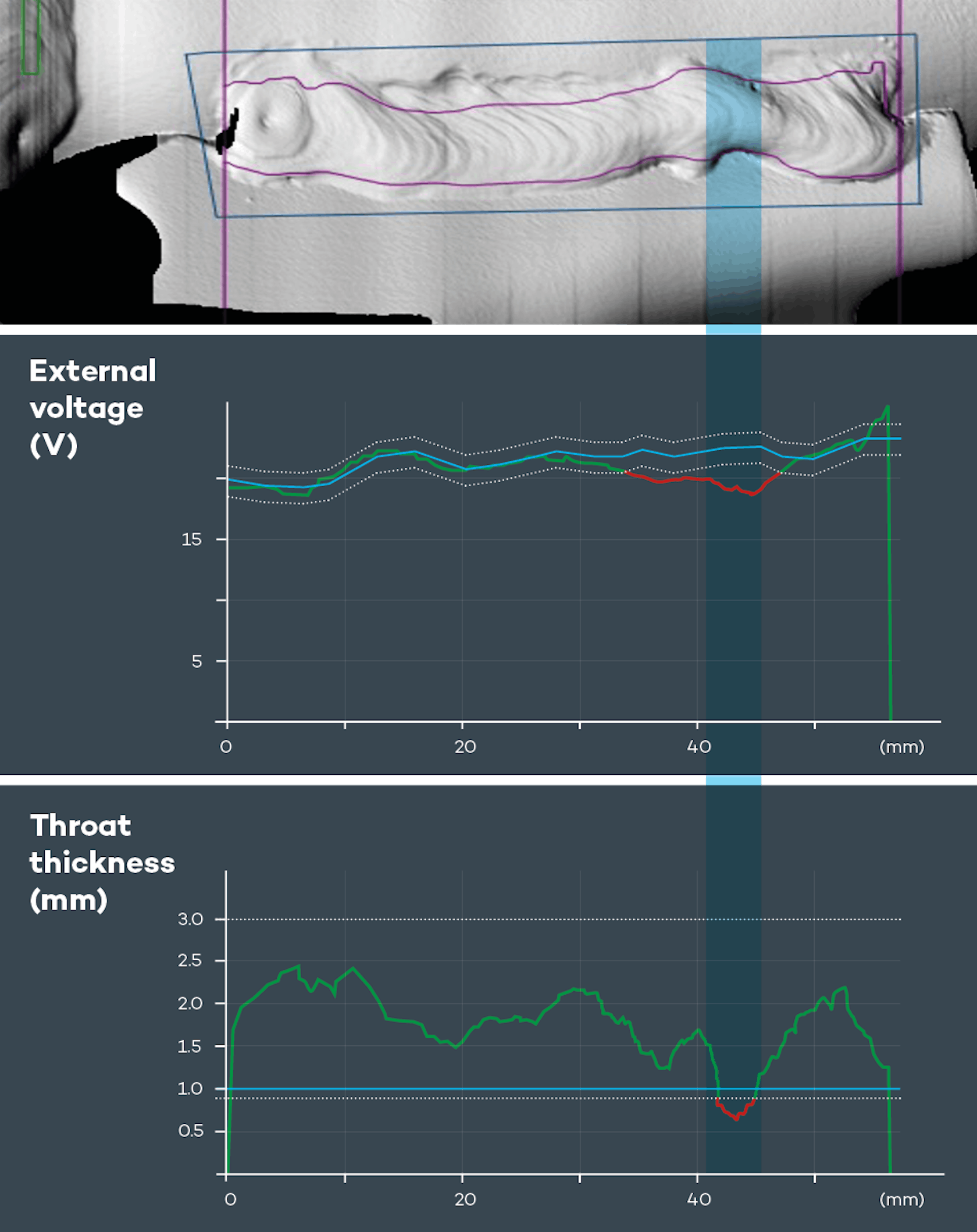

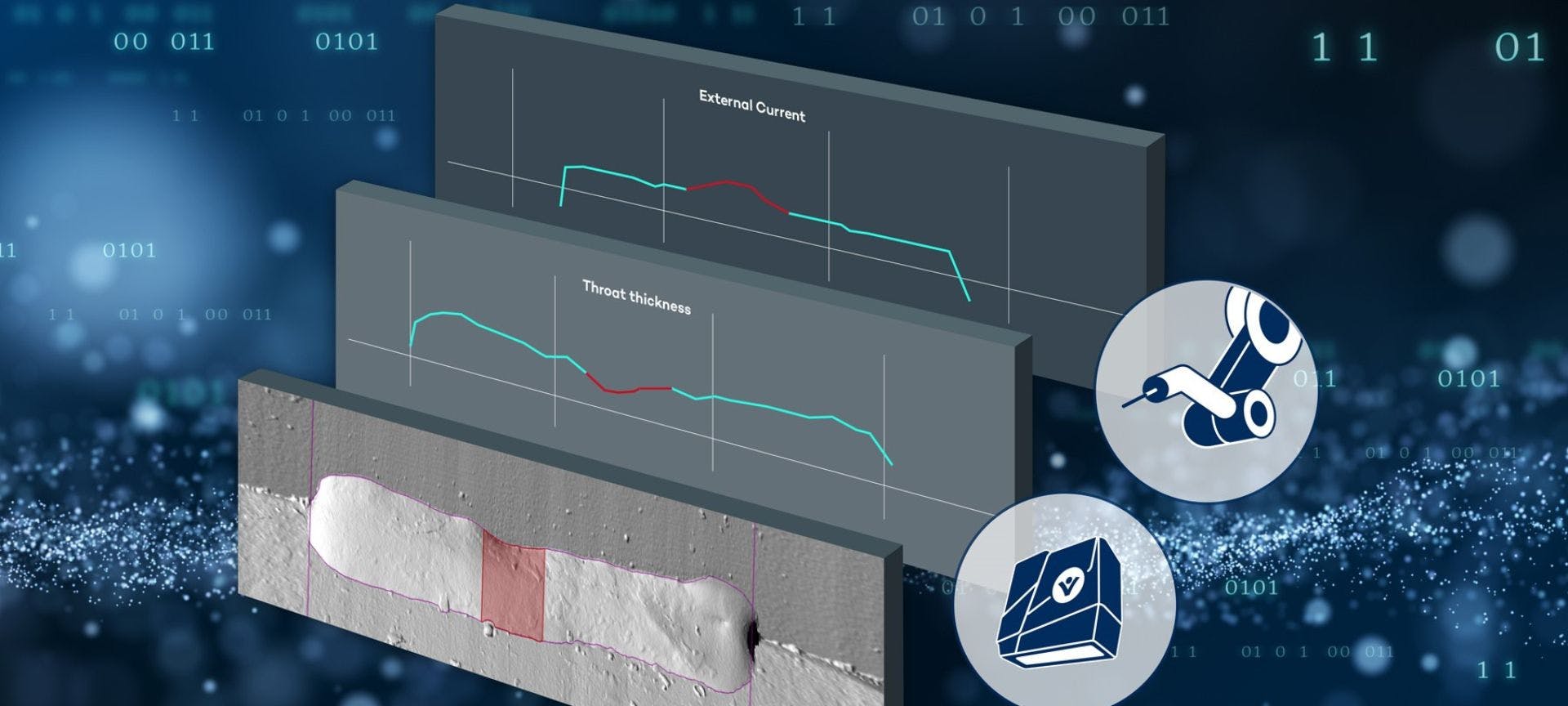

First, software analyzes the most frequent errors and their correlation with the process data and the geometric data of the weld. The following graphic shows how software displays correlations between optical image data, measured inspection data and process data. The incorrect throat thickness can thus easily be traced back to the voltage drop:

This type of analysis doesn’t only work for individual production parts. Using various reports and visualizations, large amounts of data can be displayed, such as different measured values of several seams over a certain period of time.

In the example shown below, two values are compared for several seams: The seam volume calculated from the wire feed and the measured 3D data of the seam. Large scattering of points of the same color indicate here that the weld metal runs into a gap.

Likewise, you can collect and analyze data for an extended period of time to find trends and causes of common errors. In the future, artificial intelligence (AI) will support the optimization process: It analyzes all captured data, recognizes patterns, identifies potential sources of errors and suggests measures.

The optimization potential for your welding process

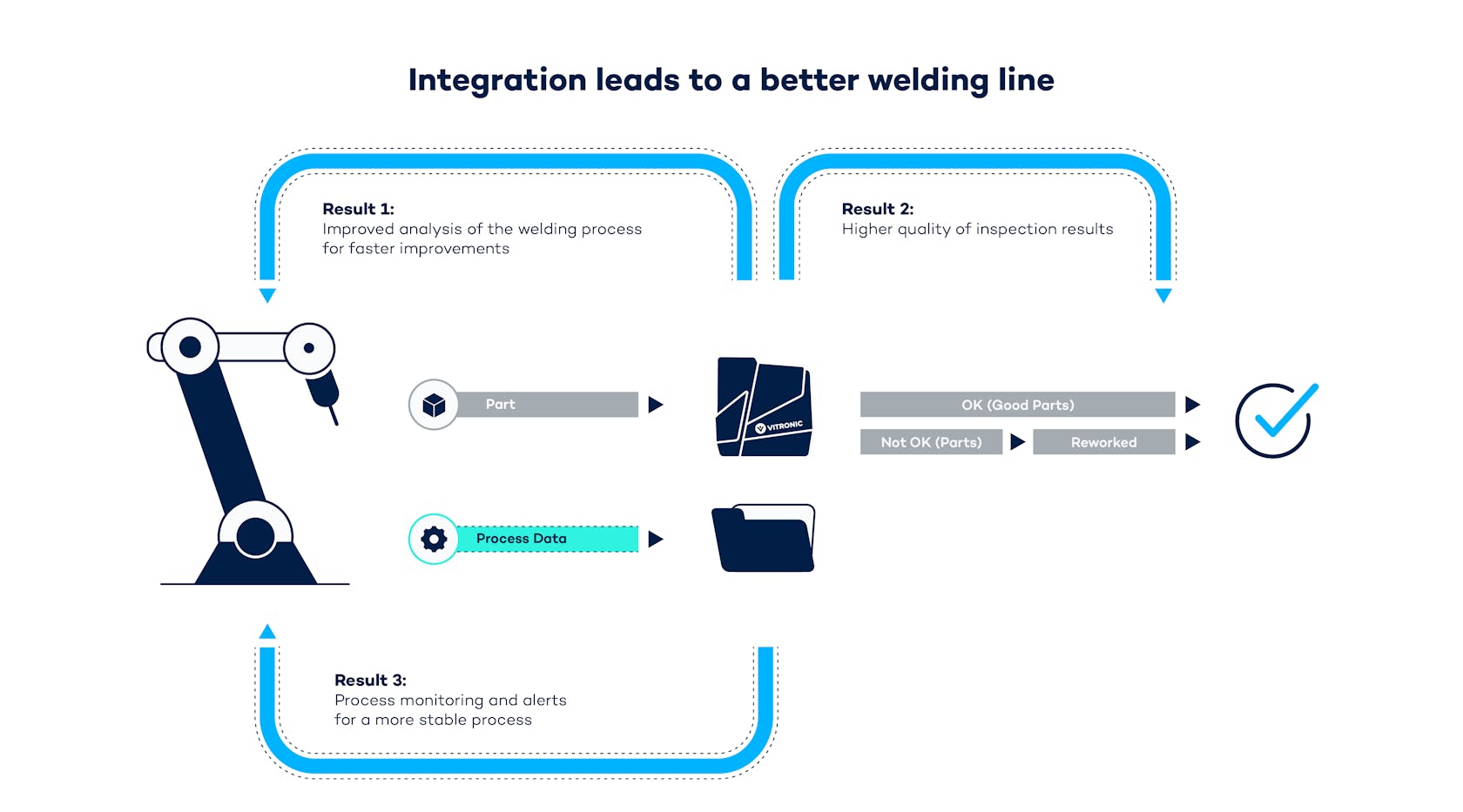

How do you optimize your welding line by linking this data? You can achieve three results:

- As already shown, you can recognize a large part of the causes of errors immediately and make optimizations right away.

- You can optimize the accuracy of the inspection itself and, above all, minimize pseudo defects (false negative inspections). In addition to the image data, the inspection unit has the process data available for analysis. Based on this data, it could decide, for example, whether to evaluate a weld seam as still "within tolerance" or to report a defect.

- If discrepancies in the process frequently lead to errors, these could be corrected by a feedback process already during welding.

As a result, you get more stable welding processes, reduce downtime and lower scrap.

The self-optimizing welding line – just a matter of time

Can you automize the optimization process – just as series production itself already works without manual intervention at many points?

Not yet. However, it is only a matter of time. Artificial intelligences learn with every additional data set and every detected error. They can recognize patterns and correlations better and better and draw conclusions: that is the essence of so-called machine learning.

If, for example, a certain voltage drop has already caused a welding defect 1,000 times, it is very likely that it will do so again the 1,001st time. The AI could then intervene and would most likely be correct.

A closed loop with the integration of data from different process steps leads to higher productivity in the welding process and to higher safety in automated quality inspection. In the future, defined process improvements and preventive interventions will become possible without human intervention.

This way, a welding line becomes a closed-loop system that continuously collects and evaluates data, optimizes itself and, ideally, intervenes before errors occur.

Important: You decide which actions you want to allow the software to perform and which require human approval. As the person responsible for the welding process, you retain sovereignty over the optimization – the system supports you in this.

Summary

In short

- You should record data as completely as possible at every point along the welding line.

- By linking inspection and process data, you can immediately identify the cause of around 60 percent of all welding defects.

- With the data, you can optimize both the welding process and the inspection.