Automatic Dimensioning for PalletsCapture freight in less than a second

Fully automated pallet measurement for more efficient logistics

Automatic Dimensioning for Pallets

Pallets are everywhere in logistics, which is why their fast, reliable handling is a decisive factor for success.

Automated dimensioning of pallet volume accelerates and simplifies freight handling and shipments, while ensuring accuracy and seamless data integration. This reduces, if not eliminates, costly delays, manual errors, and unnecessary shipping costs.

Efficient logistics, detailed documentation

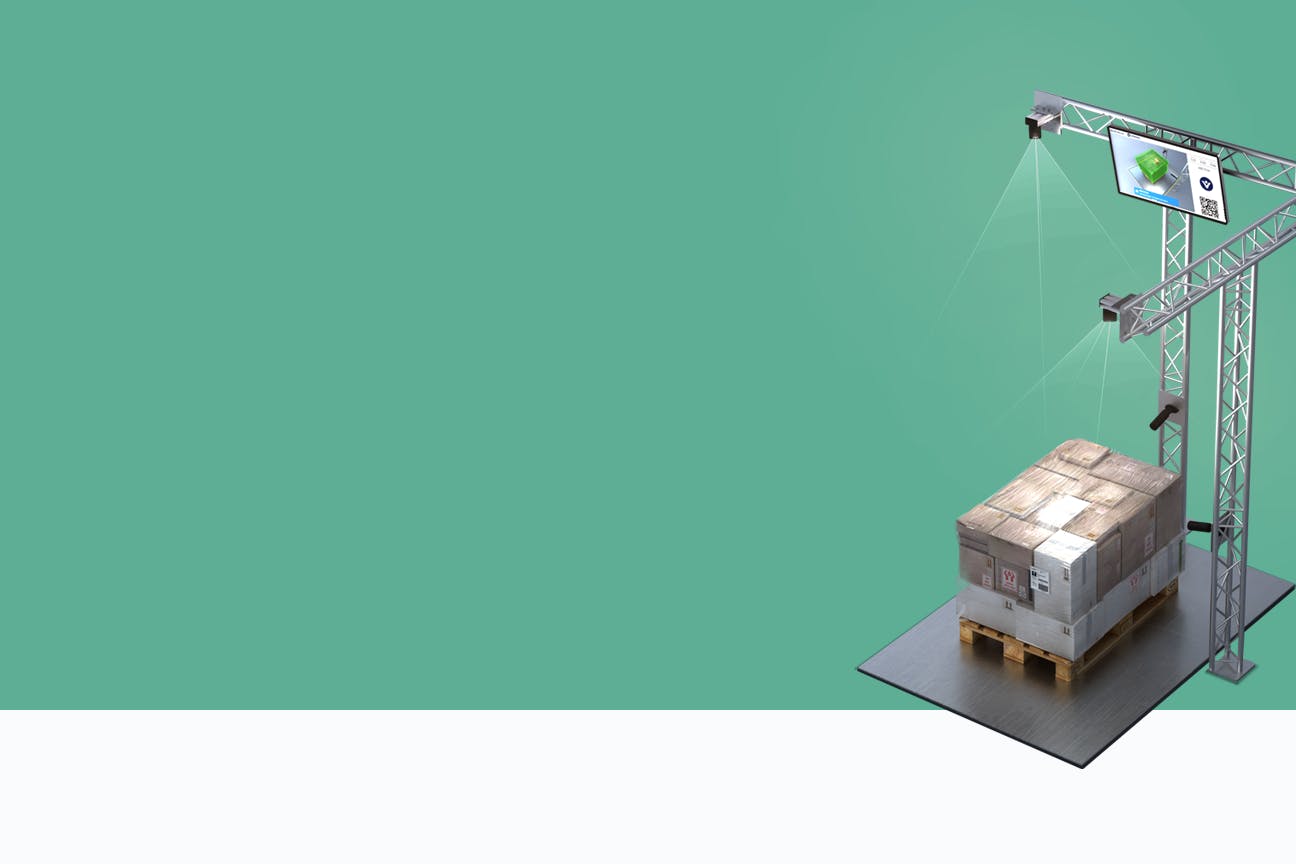

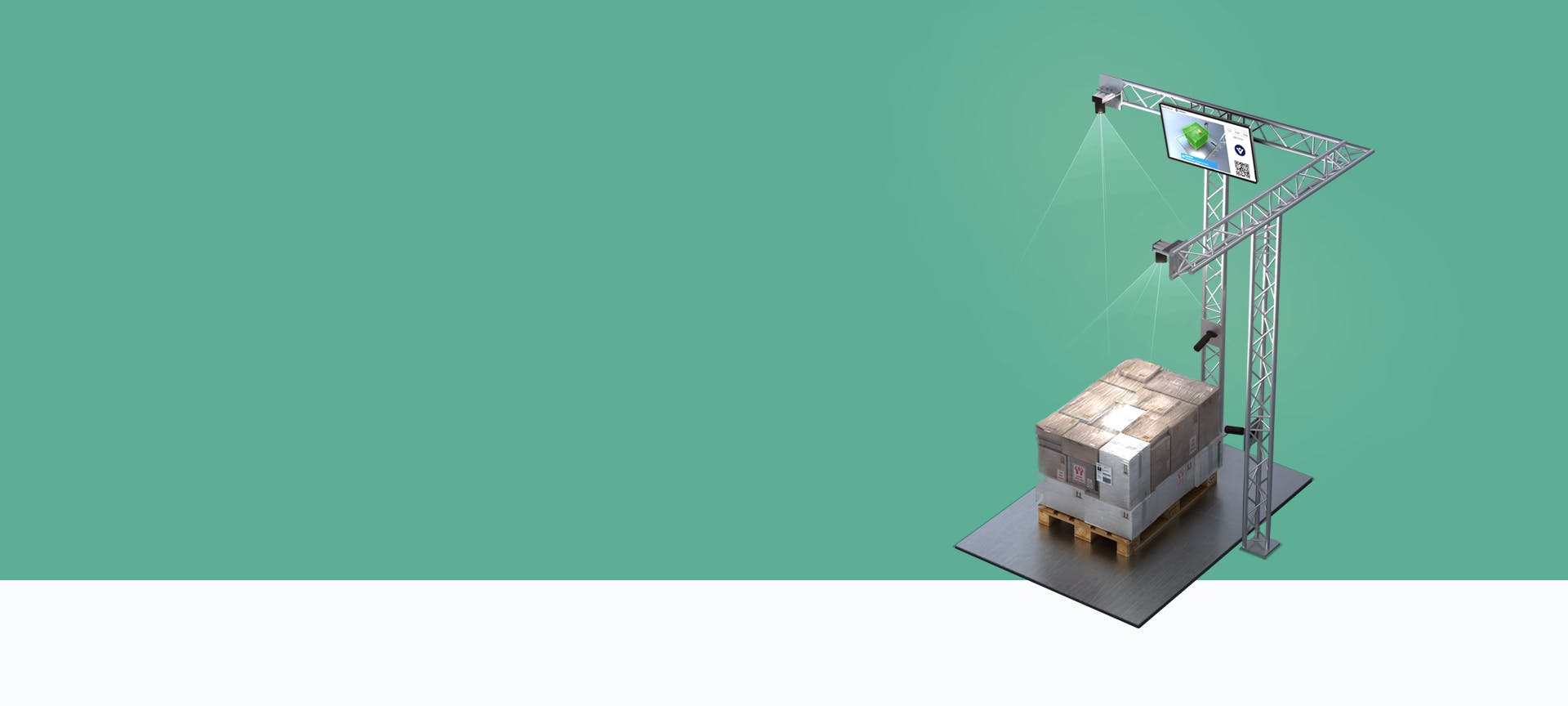

With VIPAC Pallets, VITRONIC offers a static measurement system that captures palletized freight in less than a second. Two to six time-of-flight (ToF) cameras create a three-dimensional image and deliver a point cloud of the pallet goods, from which the exact volume is immediately determined. All the information is automatically transmitted to the operator and the ERP system in real time, which not only streamlines subsequent processes, but also prevents billing disputes, inaccuracies, and errors, thanks to the consistent digital documentation.

The technology can process large and multiple objects simultaneously and also recognize non-stackable pallets.

- ≤600pallets/hour

How automated pallet dimensioning streamlines your logistics

Valuable Data, systemic revenue recovery

The precise pallet measurement system not only enables optimal use of valuable storage space and improved loading of containers, trucks, and other means of transport, but it also optimizes freight costs and supports certified invoicing by meeting the highest standards for legal-for-trade measurements. The state-of-the-art technology captures the volume of goods, as well as their density, handling, stowability, and liability, resulting in more accurate classifications.

VIPAC Pallets is NMFC, NTEP, MID, and OIML certified, meaning that the measured data can be used for billing purposes at any time.

VIPAC Pallets provides measurable benefits from day one. The solution is compact and designed to be easily incorporated into the infrastructure of any warehouse in less than a day. It can be installed as a ceiling-mounted, gate, or V-shaped system above a floor scale or conveyor, and it is immediately operational, thanks to its minimal hardware requirements and seamless plug-and-play integration into existing processes.

Maintenance-free design

Accurate stackability classification with Non-Stackable Pallets Add-on

The Non-Stackable Pallets (NSP) Add-On expands the pallet measurement solution with an automatic stackability check and gives billing teams solid evidence for surcharge decisions. It adds additional vision and smart software to the existing measurement tools, so every pallet gets a simple go-or-no-go answer. Results appear right away, including an explanatory AI note and link to clear photos that support operational calls and invoicing.

Additionally, functions such as color cameras for capturing freight from all sides, customized reports with defined measurement data and images, and weighing in addition to pallet measurement can be added.